HVC - High Voltage Capacitors

Holy Stone high voltage products are designed and manufactured to meet the general requirements of international standards. The product offering is well suited for commercial and industrial applications and includes NO0 (G0G) and X7R characteristics in sizes 0805 to 2225 and with working voltages from 1KV up to 5KV.

Core Features

- Special internal electrode design offers the highest voltage rating

- Surface mount suitable for wave and reflow soldering

- High reliability

- RoHS compliant

Applications

- Suitable for LAN/WLAN interface, Back-lighting Inverters, DC-DC Converters, Ballast, Modems, and Power Supplies.

- SiC & GaN systems, Snubber, Resonant Circuit (LLC, Wireless charging, etc.)

Summary of Specifications

| Operation Temperature | -55℃ to +125 ℃ | |

| Rated Voltage | 1KVdc to 5KVdc | |

| Temperature Coefficient | NP0 : ≤ ± 30ppm/ ℃ | -55 C to +125 ℃ (EIA Class I) |

| X7R : ± 15% | -55 C to +125 ℃ (EIA Class I) | |

| Dissipation Factor |

NP0 : Morethan 30pF Q≥1000 ; 30pF & below Q≥400+20 C |

|

| Insulation Resistance | 10GΩ or 500/C Ω, whichever is smaller | |

| Aging | NP0 : 0% ; X7R : 1.0% per decade of time | |

| Dielectric Strength | 100V ≤ V < 500V | 200% rated voltage |

| 500V ≤ V < 1000V | 150% rated voltage | |

| 1000V ≤ V | 120% rated voltage | |

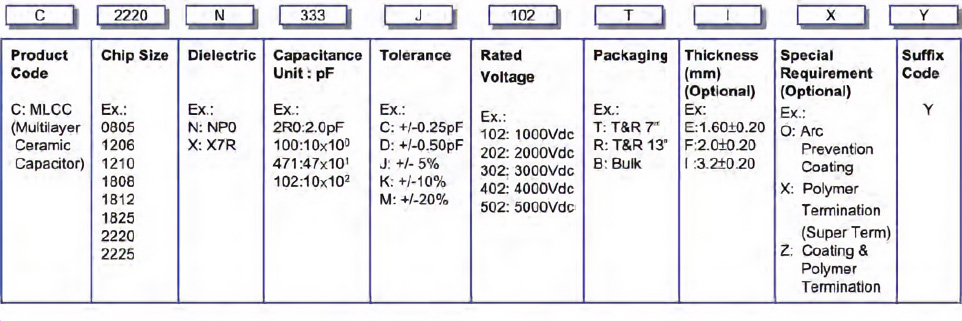

How To Order

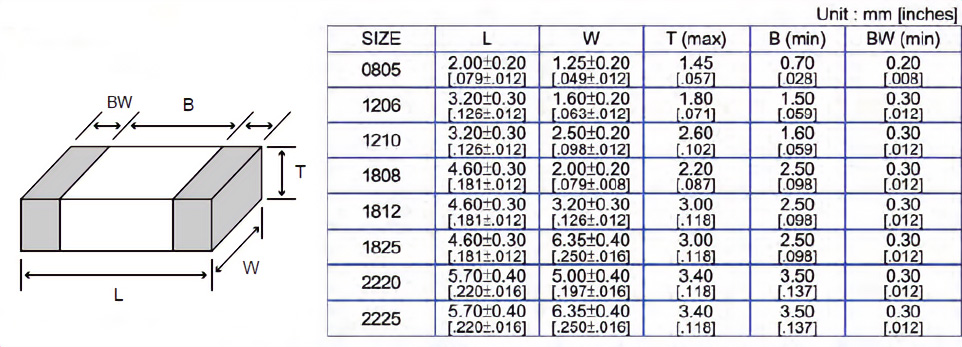

Dimensions

Capacitance Range - NP0 / 1KVdc to 2KVdc

Capacitance Range - NP0 / 3KVdc to 5KVdc

- The yellow indication denotes values that are under development. Please contact the Holy Stone office for further details

- Other dimensions, capacitance values, and voltages are available upon request.

Thickness Specification

| Symbol Code | B | C | D | E | F | G | H | I |

| Thickness(mm) | 0.85±0.15 | 1.0+0.1/-0.05 | 1.25±0.20 | 1.6±0.2 | 2.0±0.2 | 2.4±0.2 | 2.8±0.2 | 3.2±0.2 |

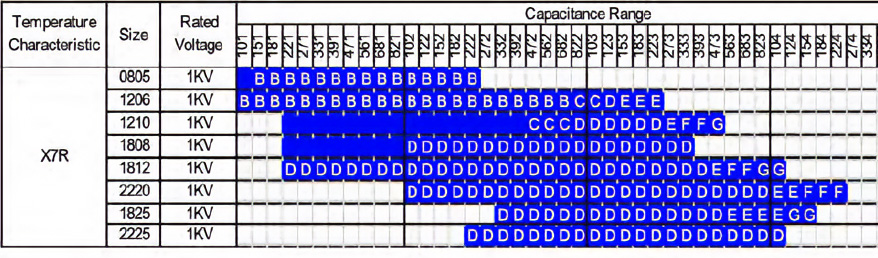

Capacitance Range - X7R / 1KVdc

Capacitance Range - X7R / 1.5KV to 2.5KV

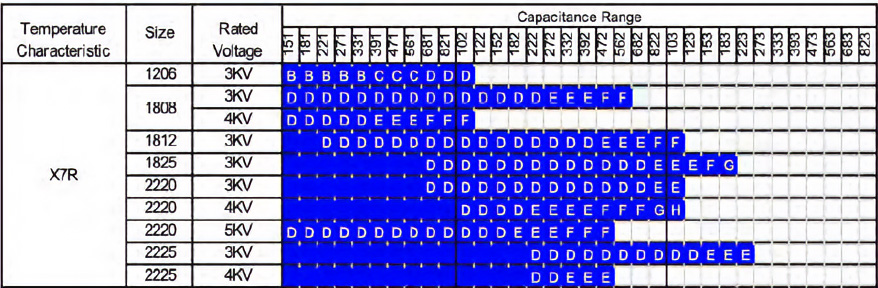

Capacitance Range - X7R / 3KVdc to 5KVdc

Thickness Specification

| Symbol Code | B | C | D | E | F | G | H | I |

| Thickness(mm) | 0.85±0.15 | 1.0+0.1/-0.05 | 1.25±0.20 | 1.6±0.2 | 2.0±0.2 | 2.4±0.2 | 2.8±0.2 | 3.2±0.2 |